Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

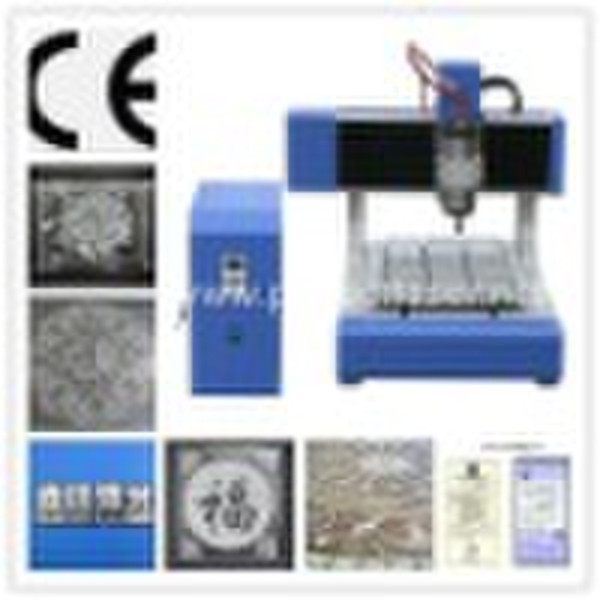

CNC Router (PEM-3030)

Cathy Liu

Contact person

Basic Information

PEM-3030 CNC RouterFeature This model carries on high-speed main axis, cooling of water circulation, it has little noise and pollution. 1. non-decelerating curve 2. Precise data and numerical value 3. Easy operation X, Y, Z axis use imported ball bearing guide screws. Its precise and fast. Even the letters of 1mm can be clearly discernible. The small-power machine uses large-power main axis, its an ideal product for manufacturing labels, construction models and moulds in batches. High speed calculation It uses DSP64 contouring control system and FPGA technology which can continually and smoothly run the three axes with high speed. It has the ability of calculation of 5000 vector/s. Steady data transmission The data transmission uses the technology of ISA/IP DNC/IP straight association, which can associate the machine without interruption, and it has no limitation of the amount of the document. Double-nut guide screw It uses Germany-imported high-precision ball bearing guide screw which can eliminate cracks automatically. Coordinated with the imported shaft coupling, it can realize precise control. It uses straight line guide rail (cylinder or square), which can ensure the working life.Introduction The engine bed is made from pure Aluminum, which ensures the parallelism, verticality and concentricity and greatly increases the precision and speed of the engine bed. It is applied in cutting of kneading board of large size and making of large-scale relief and label. The size of the machine is calculated and customized according to optimization rules in market Statistics. It covers main sizes of marks and labels in the market. It can cut through Plexiglas with thickness of 20mm one time without trouble and can be applied to large-scale relief, too. It is doubtlessly a perfect product in the range of ad engraving. Parameter Performance index Normal value Power stroke of X,Y,Z axis 300×300×120mm Size of working table 500×800mm Power of main axle 1.5KW Running location precision of X,Y,Z axis +/-0.03mm Repeating location precision of X,Y,Z axis +/-0.01mm Power stroke of Z axis 120mm Working style Stepping motor Spindle speed of frequency conversion main axis 600024000rpm/min Working voltage AC220V/50HZ Engraving order G Code.uoommg Optional main axis and Cartridge φ3.175.φ6 XY Running sensitivity 0.02mm

Delivery terms and packaging

Packaging Detail: Sea-Worthy Packing or Air-Worthy Packing Delivery Detail: 20days

Payment term

Letter of credit

Telegraphic transfer

Western Union

-

Payment Methods

We accept: